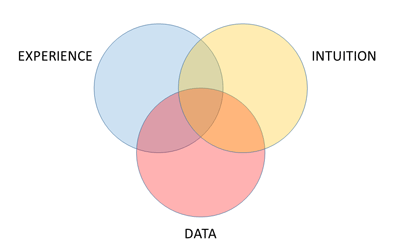

Intuition plays a critical role in all stages of a design exploration study, from defining the problem statement to building the simulation model to interpreting the results. But what about the search process itself? Should we make design improvements based on intuition, or should we allow a mathematical search engine to explore the design space for better designs? The answer is both. We call this shared process collaborative design exploration.

The SHERPA search strategy allows you to inject your design ideas before and during an exploration study. Before you start a study, you can seed it with multiple ideas (in the form of actual designs) that might help SHERPA to locate productive regions of the design space more quickly, thus speeding up the overall search. For example, in addition to the baseline design, you might consider seeding the study with other potentially good designs that:

you have investigated or produced in the past

you have investigated or produced in the past- your competitors have used

- are feasible, but perhaps not optimal

- are high performing relative to one or more criteria, but not all of them

- have some desirable features, but don’t necessarily perform well

- you have a hunch may work well

- are from a previous HEEDS MDO study

One or more of these injected ideas might contribute to a more efficient search, while the cost of doing this is only the time to enter the variable values that define each of the designs. SHERPA will evaluate the injected designs when the search process is launched, so there is no need to simulate them before injection. Continue reading

A common design scenario is to optimize the number and location of certain design features to satisfy performance goals and requirements. For the sake of discussion, let’s consider a specific example of this type of problem.

A common design scenario is to optimize the number and location of certain design features to satisfy performance goals and requirements. For the sake of discussion, let’s consider a specific example of this type of problem.  Many engineers still resist the use of optimization algorithms to help improve their designs. Perhaps they feel that their hard-earned intuition is just too important to the solution process. In many cases, they are right.

Many engineers still resist the use of optimization algorithms to help improve their designs. Perhaps they feel that their hard-earned intuition is just too important to the solution process. In many cases, they are right. I am currently training to compete in my first sprint triathlon race. Well, compete may be an exaggeration, and there won’t be much sprinting. But I do hope to cross the finish line before the sun sets.

I am currently training to compete in my first sprint triathlon race. Well, compete may be an exaggeration, and there won’t be much sprinting. But I do hope to cross the finish line before the sun sets. “Creativity is just connecting things. When you ask creative people how they did something, they feel a little guilty because they didn’t really do it, they just saw something. It seemed obvious to them after a while. That’s because they were able to connect experiences they’ve had and synthesize new things. And the reason they were able to do that was that they’ve had more experiences or they have thought more about their experiences than other people.”“Unfortunately, that’s too rare a commodity. A lot of people in our industry haven’t had very diverse experiences. So they don’t have enough dots to connect, and they end up with very linear solutions without a broad perspective on the problem. The broader one’s understanding of the human experience, the better design we will have.”

“Creativity is just connecting things. When you ask creative people how they did something, they feel a little guilty because they didn’t really do it, they just saw something. It seemed obvious to them after a while. That’s because they were able to connect experiences they’ve had and synthesize new things. And the reason they were able to do that was that they’ve had more experiences or they have thought more about their experiences than other people.”“Unfortunately, that’s too rare a commodity. A lot of people in our industry haven’t had very diverse experiences. So they don’t have enough dots to connect, and they end up with very linear solutions without a broad perspective on the problem. The broader one’s understanding of the human experience, the better design we will have.”