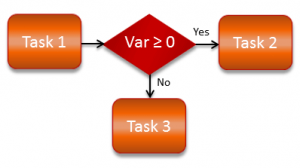

The process definition now provides support for the use of logic to drive the flow in the analysis process. One or more conditions can be defined at the analysis level to control whether an analysis will be attempted. Several scenarios that would have required specialized external scripts to capture the desired process behavior are now easily handled with this feature. Some of these scenarios are listed below:

The process definition now provides support for the use of logic to drive the flow in the analysis process. One or more conditions can be defined at the analysis level to control whether an analysis will be attempted. Several scenarios that would have required specialized external scripts to capture the desired process behavior are now easily handled with this feature. Some of these scenarios are listed below:

- Improve efficiency in the evaluation process by skipping compute intensive analyses when it is clear that the design would not be acceptable

- Continue execution of the process even when some of the analyses result in errors

- Use of an appropriate physics model based on the results of an upstream analysis

Example

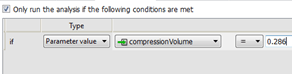

Consider the following example where the goal is to optimize the piston bowl shape to improve the performance and the emissions. One of the requirements for each design is to have the compression volume stay constant. This is achieved by performing a local optimization within the CATIA analysis. This local optimization process does not result in the desired compression volume for all design configurations. In cases where the desired volume is not obtained, it would be best to not evaluate the compute intensive simulation since the design is not acceptable.

|

|

|

|

| Simulation Time | 5 minutes | 2 minutes | 6 hours |

| Conditions | No conditions | No conditions |  |

For this study, if we ran an optimization with 100 design iterations, the time savings are considerable even if only 20% of the designs failed to meet the volume requirement.

Time savings = 20 * 6 = 120 hours