Simcenter SPEED is an all-in-one specialized tool for the sizing and preliminary design of electric machines such as motors, generators and alternators. This software provides a built-in graphical user interface to access HEEDS in two ways: as a full HEEDS installation and as an integrated add-on tool. HEEDS enables Simcenter SPEED to automate and intelligently explore the design space resulting in increased machine efficiency at a lower cost.

Combined with STAR-CCM+, Simcenter SPEED offers design engineers a unique and powerful ability to model electromagnetic and flow/thermal capabilities in the same working process. This results in an end-to-end multiphysics solution for electric machine design and allows for thermal and stress management under a wide range of environmental conditions, leading to more affordable and better performing electric machines.

Simcenter SPEED benefits and features at a glance:

- Electric machine template: set-up an electric machine model in minutes

- Multi-physic software link: seamless import to Finite Element software

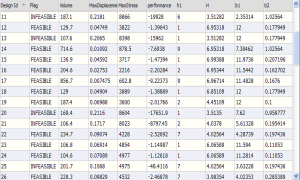

- Design space exploration: automatically optimize electric machine performance with HEEDS

- System level simulation: model export to system level model within Simcenter Amesim

Download the Simcenter SPEED fact sheet

Download the Simcenter SPEED Rapid Electric Machine Design Spotlight

Read more about Simcenter SPEED here

A common design scenario is to optimize the number and location of certain design features to satisfy performance goals and requirements. For the sake of discussion, let’s consider a specific example of this type of problem.

A common design scenario is to optimize the number and location of certain design features to satisfy performance goals and requirements. For the sake of discussion, let’s consider a specific example of this type of problem.  What are the three most important things to consider when buying a house? Location. Location. Location. The repetition intentionally over-emphasizes this point: if the location of your new real estate purchase is not good, then the details of the home don’t really matter.

What are the three most important things to consider when buying a house? Location. Location. Location. The repetition intentionally over-emphasizes this point: if the location of your new real estate purchase is not good, then the details of the home don’t really matter. You may have heard the story about the woman who always sliced about one inch off the end of a large roast before placing it in the pan to be cooked. When asked why she did this, she did not know the reason. But she was sure that it was important, because her mother always did exactly the same thing.

You may have heard the story about the woman who always sliced about one inch off the end of a large roast before placing it in the pan to be cooked. When asked why she did this, she did not know the reason. But she was sure that it was important, because her mother always did exactly the same thing. Despite these impressive exhibitions, machines cannot think like humans – yet. For example, given different sets of information, humans have a natural ability to detect patterns and perceive order. Computers, on the other hand, must be told what types of pattern structures to look for.

Despite these impressive exhibitions, machines cannot think like humans – yet. For example, given different sets of information, humans have a natural ability to detect patterns and perceive order. Computers, on the other hand, must be told what types of pattern structures to look for. When the chainsaw was first introduced, I wonder how many lumberjacks tried dragging it back and forth against a tree, expecting it to work the same way as a hand saw. Figuring out the best use of a new technology is just as important, and sometimes as difficult, as developing the technology in the first place.

When the chainsaw was first introduced, I wonder how many lumberjacks tried dragging it back and forth against a tree, expecting it to work the same way as a hand saw. Figuring out the best use of a new technology is just as important, and sometimes as difficult, as developing the technology in the first place. When martial artist Bruce Lee offered the above advice about being adaptable, I doubt that he was referring to mathematical optimization. But these words of wisdom are certainly relevant to optimization algorithms.

When martial artist Bruce Lee offered the above advice about being adaptable, I doubt that he was referring to mathematical optimization. But these words of wisdom are certainly relevant to optimization algorithms. When computer aided engineering (CAE) analysis techniques, like the finite element method, were first introduced, their primary role was to investigate why a design failed. Surely, this understanding would help designers avoid such failures in the future.

When computer aided engineering (CAE) analysis techniques, like the finite element method, were first introduced, their primary role was to investigate why a design failed. Surely, this understanding would help designers avoid such failures in the future. However, often we don’t have enough time or computing resources to carry out the number of design evaluations that would be needed to find the optimal solution. In these cases, we have no choice but to relax our goal and to seek the greatest possible design improvement within the available time.

However, often we don’t have enough time or computing resources to carry out the number of design evaluations that would be needed to find the optimal solution. In these cases, we have no choice but to relax our goal and to seek the greatest possible design improvement within the available time.